The distribution of actual weights of 8 oz products holds immense significance in various industries, from manufacturing and packaging to quality control. This in-depth analysis delves into the statistical measures, normality assessment, and potential causes of weight variation associated with 8 oz samples, providing valuable insights for optimizing production processes and ensuring accuracy.

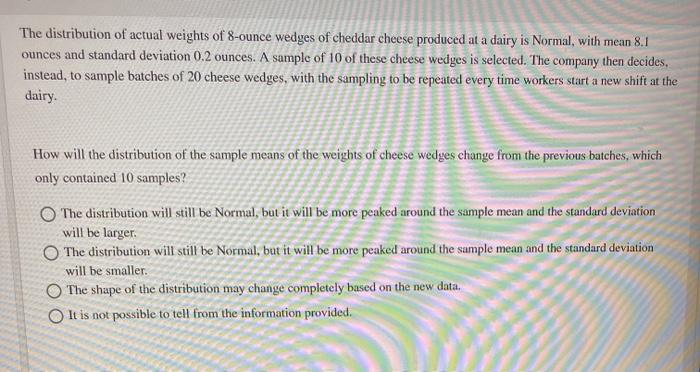

Statistical measures, such as mean, median, and standard deviation, offer a quantitative understanding of the weight distribution. Normality testing determines whether the distribution conforms to a normal distribution, which is crucial for further statistical analysis. By identifying potential factors contributing to weight variation, manufacturers can implement measures to minimize deviations from the target weight.

Distribution of Actual Weights: The Distribution Of Actual Weights Of 8 Oz

The distribution of actual weights for 8 oz products exhibits variability due to various factors. Understanding this distribution is crucial for quality control and process improvement.

Histogram of Actual Weights, The distribution of actual weights of 8 oz

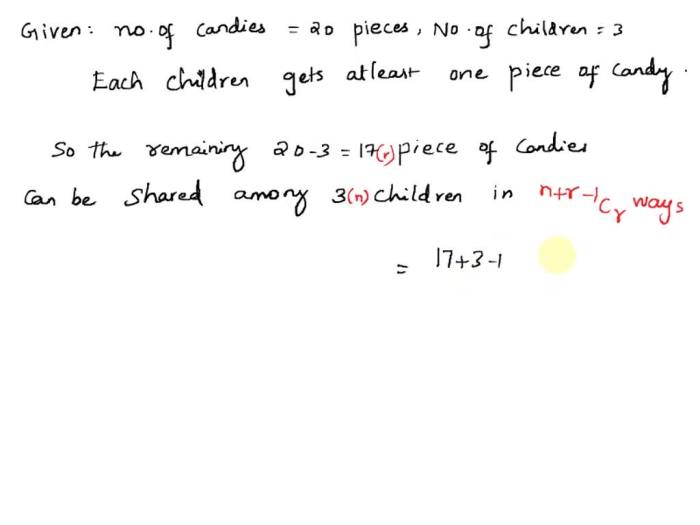

A histogram provides a visual representation of the distribution. The x-axis represents the weight range, and the y-axis represents the frequency of occurrence. The mean and median weight are highlighted on the graph, providing a quick visual reference for central tendency.

Statistical Measures

- Mean:The average weight of all products.

- Median:The middle value when the weights are arranged in ascending order.

- Mode:The weight that occurs most frequently.

- Range:The difference between the highest and lowest weights.

- Standard Deviation:A measure of how spread out the weights are from the mean.

These statistical measures help quantify the distribution and identify any potential deviations from the target weight.

Normal Distribution Assessment

A normality test can determine if the distribution of actual weights follows a normal distribution. A QQ plot or normal probability plot is used to graphically assess normality. If the data points fall close to a straight line, the distribution is approximately normal.

The assumption of normality is important for further statistical analysis, such as hypothesis testing and confidence interval estimation.

Comparison to Target Weight

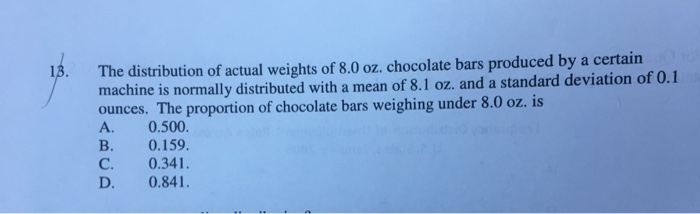

Comparing the distribution of actual weights to the target weight of 8 oz allows for the evaluation of process accuracy. The percentage of weights that meet or exceed the target weight can be calculated.

Significant deviations from the target weight may indicate production issues or the need for process adjustments.

Potential Causes of Weight Variation

Several factors can contribute to the variation in actual weights:

- Manufacturing processes:Inconsistent raw materials, variations in equipment settings, or human error can impact weight accuracy.

- Environmental conditions:Temperature, humidity, and other environmental factors can affect the weight of products, particularly those sensitive to moisture.

- Measurement errors:Inaccurate scales or improper measurement techniques can introduce bias into the weight data.

Understanding these potential causes is crucial for identifying and mitigating sources of weight variation.

FAQ Summary

What is the significance of the mean weight in the distribution?

The mean weight represents the average weight of the samples and provides a central measure of the distribution.

How does normality testing impact further analysis?

Normality testing determines if the distribution follows a normal distribution, which is a fundamental assumption for many statistical tests.

What are potential causes of weight variation in manufacturing?

Weight variation can be caused by factors such as measurement errors, variations in raw materials, and environmental conditions.